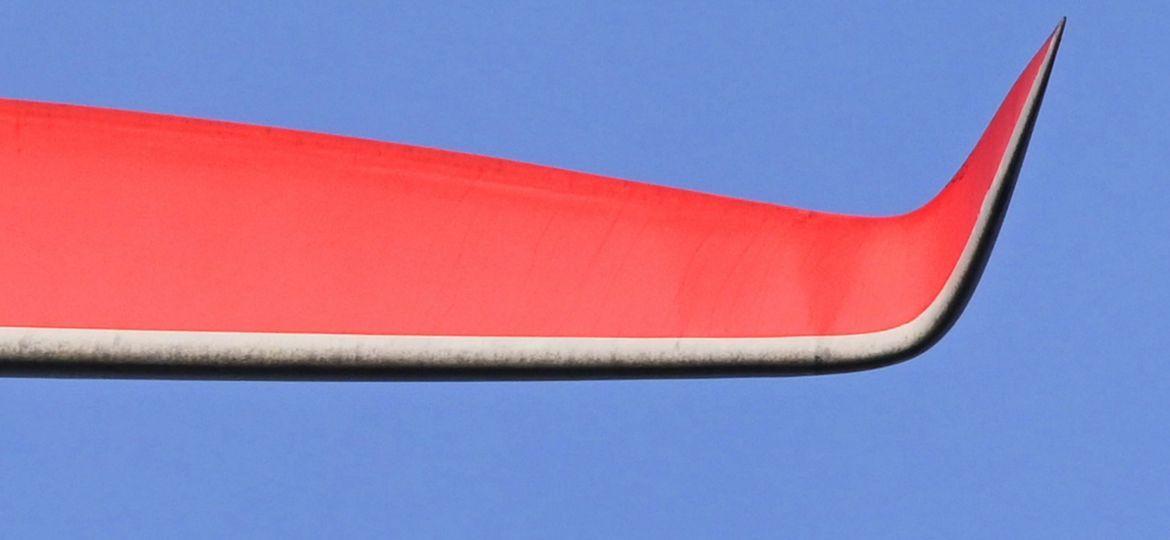

BLADE INSPECTION WITHOUT DOWNTIME

Do your turbine blades need inspecting?

Romotioncam™ is an innovative patented rotor blade monitoring technology. Romotioncam™ performs blade inspections, capturing high-resolution images for damage reports while the wind turbine remains in full operation.

Energy produced

Maintenance

without downtime

ROMOTIONCAM

Blade inspections advantages

Blade inspection innovation

Blade inspection advantages

Romotioncam

vs Drone

Three-Phase Inspection Process

Service Model

Additional Power production

Savings calculator

Energy (kWh)

The amount of energy saved by using Romotioncam.

Profit (€)

The financial benefit or profit gained from the energy savings.

powered by

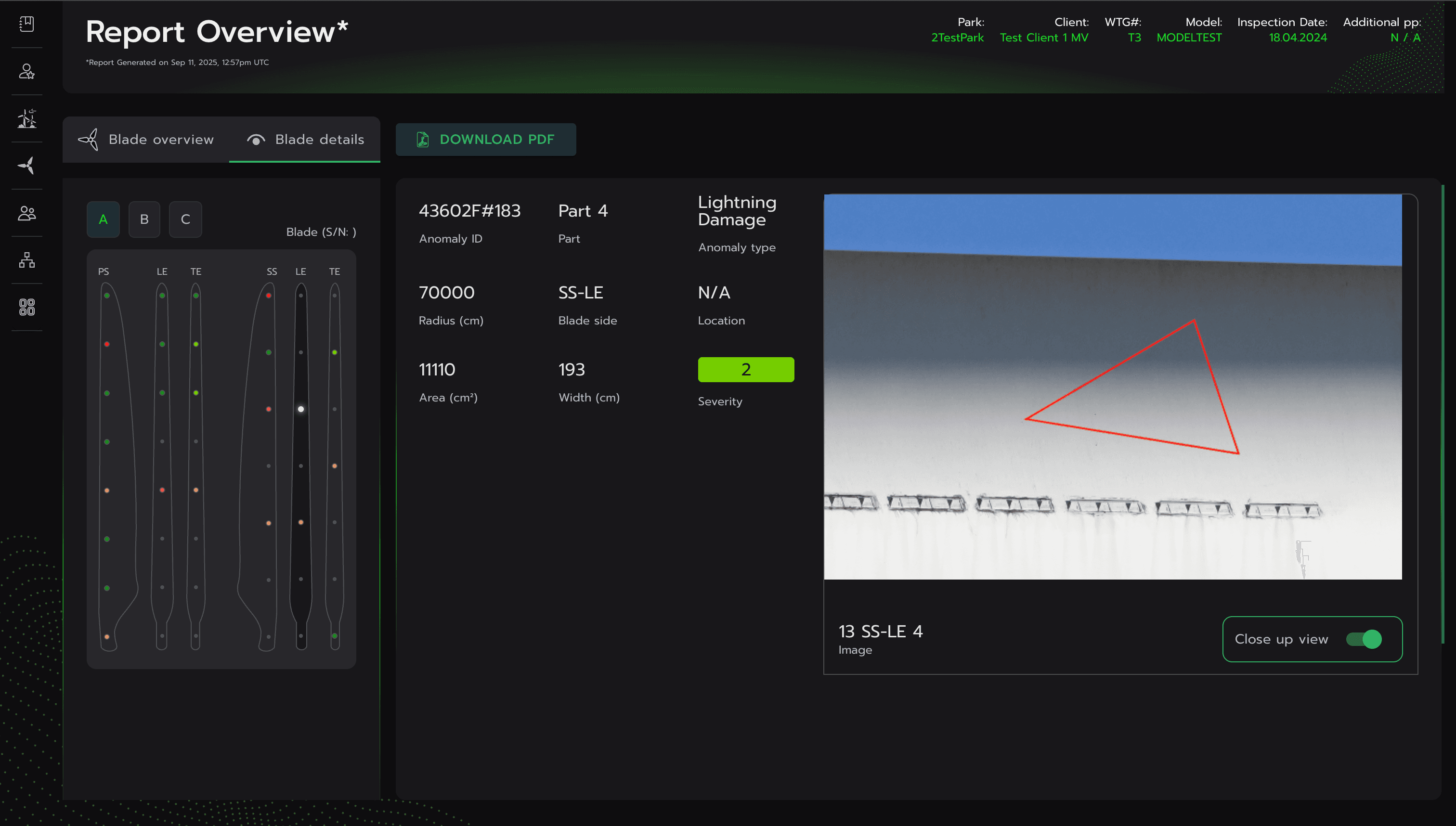

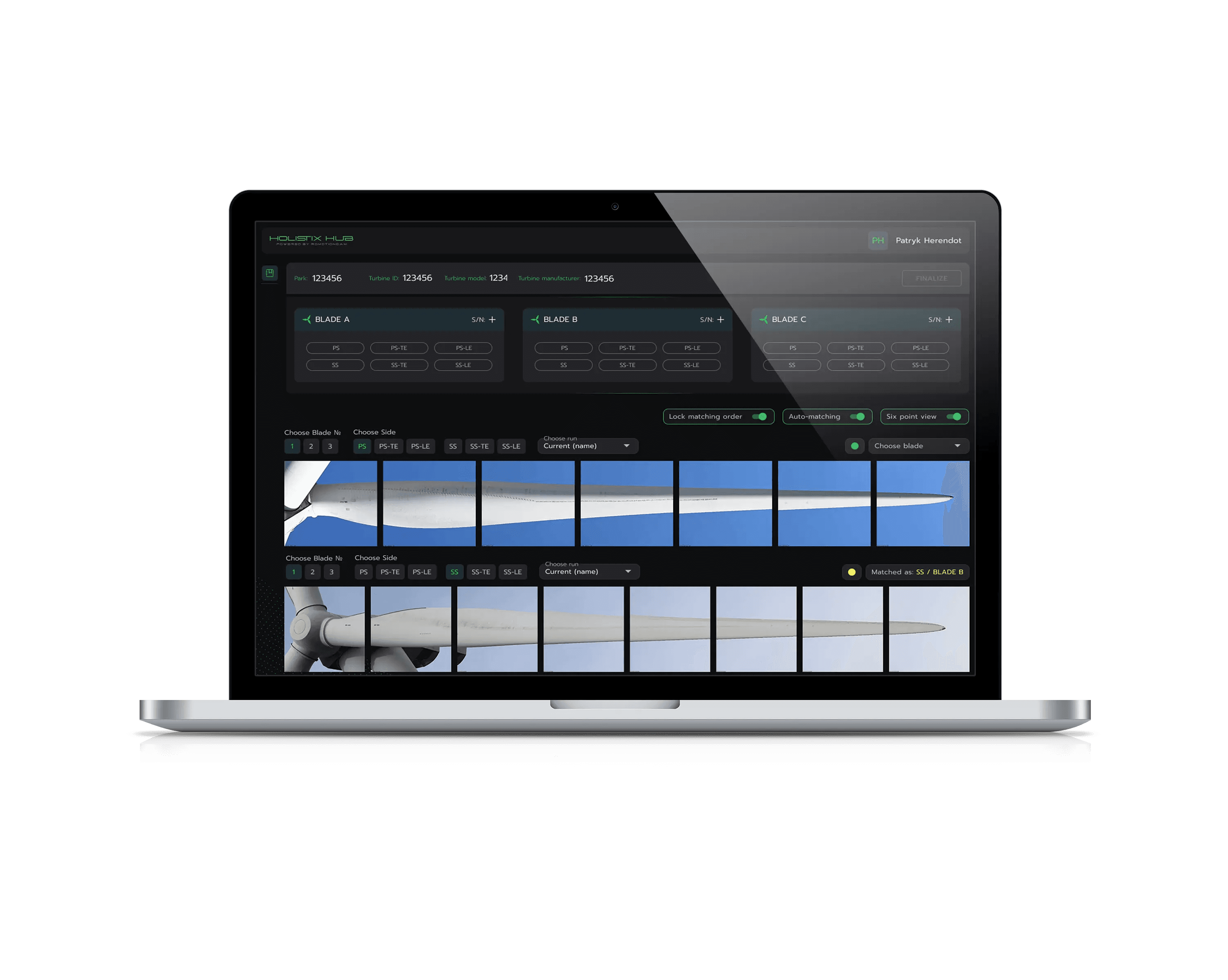

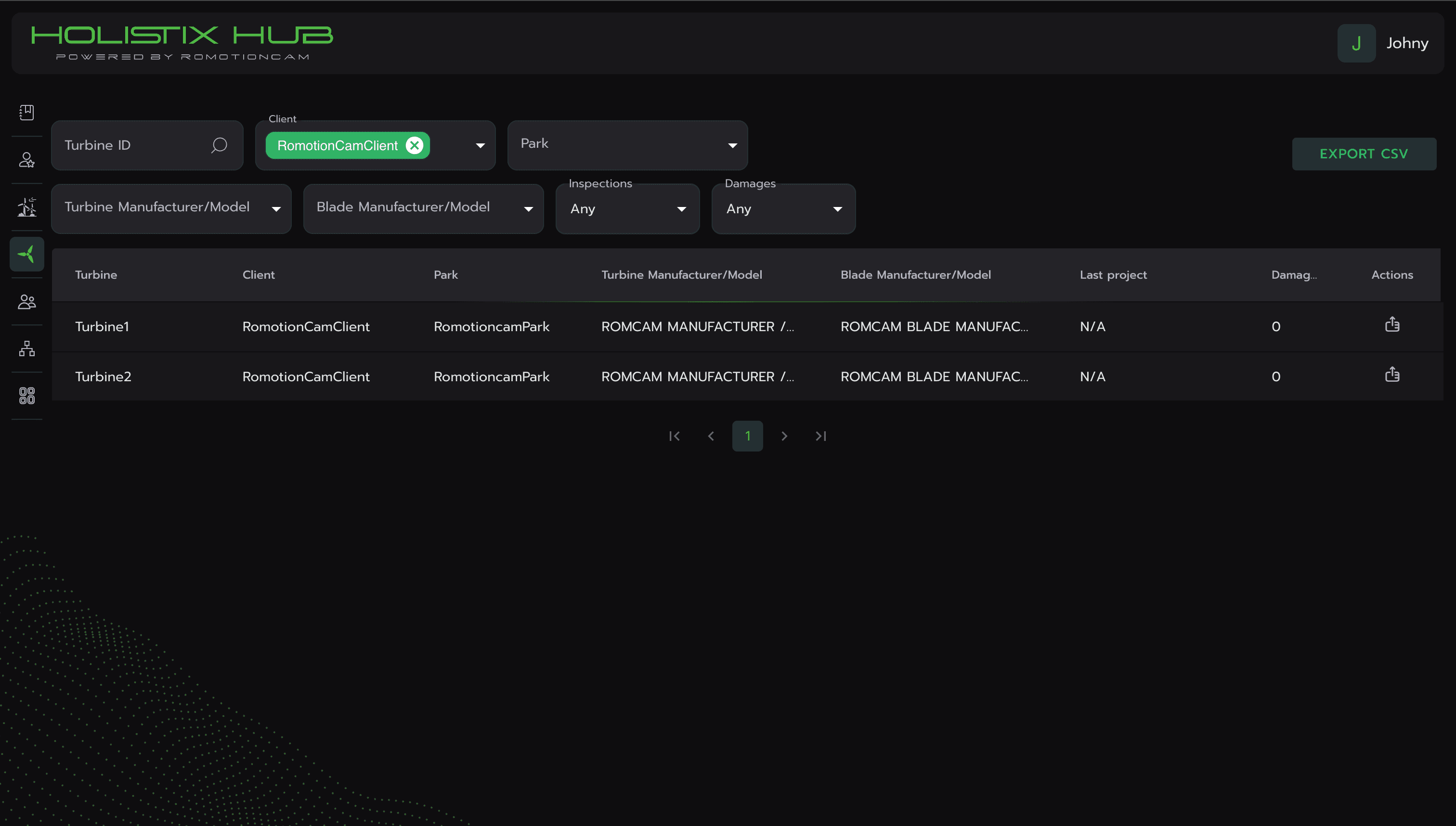

HolistixHub platform

HolistixHub empowers wind asset managers with a smarter, more efficient way to manage blade and tower inspections. Optimize decision-making and streamline maintenance planning with our advanced platform today!

View more

Reach out to us

Our Departments

Be in the loop

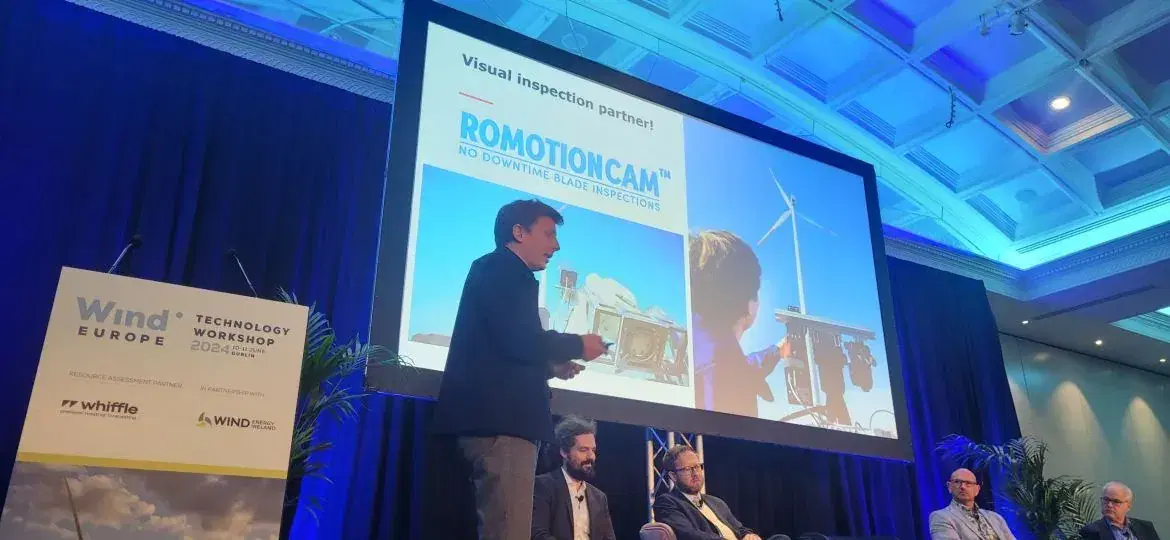

R&D and News

By collaborating with engineers, data analysts, and sustainability experts, our R&D initiatives ensure that every project reflects the cutting-edge of both visual communication and the wind energy industry.